Installation of Fill Pack & Nozzles to BAC Cooling Towers

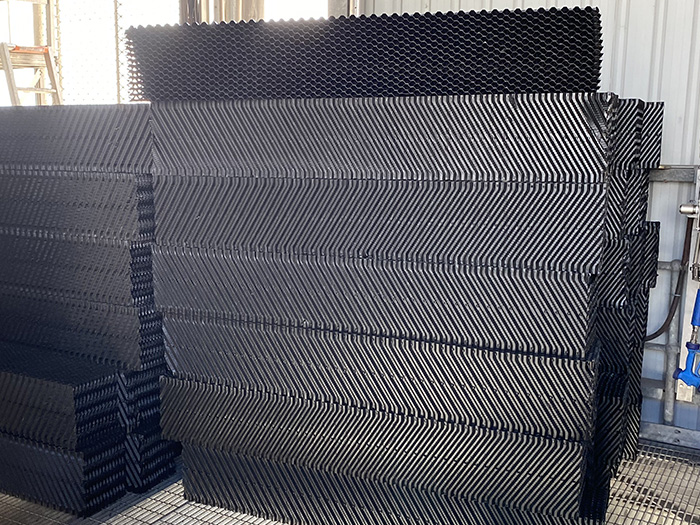

We were recently engaged to upgrade BAC Cooling Towers by installing a new Brentwood Fill Pack and replacing the nozzles. The existing Fill Pack had suffered significant damage and was no longer performing efficiently. To restore optimal heat exchange and system performance, a full replacement was necessary.

The new installation provides our client with confidence that their Cooling Tower is now operating at peak efficiency - delivering improved heat transfer, reduced energy usage, enhanced performance, and an extended system lifespan.

Our Fill Pack Installation Process:

-

Removal of the damaged Fill Pack

-

Pressure washing of the Cooling Tower to remove dirt and debris

-

Disposal of the old Fill Pack off-site

-

Installation of new, high-performance nozzles

-

Installation of Brentwood Fill Pack

-

Final quality check to ensure optimal performance

View the Fill Pack Product Page

Why Replace Your Cooling Tower Fill Pack?

-

Decreased Efficiency: Clogged or brittle Fill Pack reduces heat exchange, increasing energy consumption.

-

Wear and Tear: Exposure to high temperatures, chemical damage, and ageing reduces Fill Pack effectiveness over time.

-

Scaling and Fouling: Hard water deposits and biological growth can permanently affect heat transfer performance.

-

Upgraded Performance: Newer Fill Pack designs deliver superior efficiency and longer operational life.

Is your Cooling Tower underperforming?

Contact us today for expert advice and a free quote. Our team is ready to deliver high-performance solutions tailored to your Cooling Tower needs.